Fully automated compact and durable wet processing tool Excellent for flexibility and variable process requirements. Designed for up to 8″ wafers.

Wet process system for various applications, including cleaning, etching, stripping and developing

Benefits

> Wet process system for various applications, including

cleaning, etching, stripping and developing

> Optimized footprint

> Superior reliability

> Unique modular construction

> Extremely maintenance-friendly

Low cost of ownership

> Maximum application versatility

> Separate exhaust on the modules

> Easy installation/upgrade of additional modules based

on a modular robot system

Features & Benefits

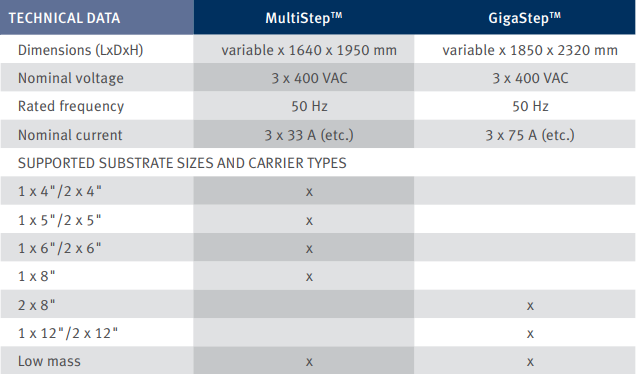

Application of different processes MultiStepTM & GigaStepTM

Many different cleans, such as RCA, IMEC, Pre-Diffusion, Pre-Metal, etc.

Various etch processes, including oxide, nitride, poly crystalline, metals and silicides

General features MultiStepTM

> Designed for substrates up to 200 mm

> Processes single 25-wafer batches of 200 mm wafers as well as double 25-wafer batches

of 100 to 150 mm wafers

General features GigaStepTM

> Designed for substrates up to 300 mm

> Processes 50-wafer batches of 300 mm

> Can also process 50 or 2 x 25-wafer batches of 150 or 200 mm wafers or masks

General features MultiStepTM & GigaStepTM

> Standard high or low profile cassette

> Modular exhaust systems for effective extraction of acid, lye, pH-neutral and solvent

produced fumes

> Dry-in-dry-out processing

> Intelligent wafer rescue and emergency actions

> Robust, simplified scheduler

Process control capabilities

> Lot tracking throughout the entire process

> Parameter tracking, including temperature, flow, resistivity, chemical dosing, etc.

> End of run filer, error files, chemistry log, user log

Graphical user interface

> Based on B&R CPU and IPC

Windows based 17-inch touch screen

> Recipe editor

> Real time digital flowcharts

> Automatic generation of diagnostic files

(EOR, ERR, ChemLog, etc.)

> Multi-tiered password levels

> Remote control via internet

Available Training

Operator, maintenance and process

Built To Comply With

FM 4910

SEMI S2 and S8

SECS/GEM

CE

Available Options

> Automated loading station wafer transfer

> Wafer ID reader

> Cassette buffer

> Dry-in-wet-out and wet-in-dry-out process capable (manual loading station Ozone system (DI-water or sulfuric acid)

> SMIF (150, 200 or 300 mm)

> Wastewater management system

> Locally installed chemical cabinets for the dilution, mixing and preheating of chemical solutions

> DI-water heating system

> Mini-environments

> Concentrate monitoring system

> POU filtration of DI-water

> Fire suppression system for solvent applications

> UPS units

> etc.

Reliability (figures based on actual tool performance)

MTBF ≥ 800 h

MTBA ≥ 300 h

Uptime ≥ 97 %

Can be delivered fully assembled