Capacitance and Current Voltage (C-V I-V) Analysis Systems

Benefits

- Customizable systems tailored by our experts to meet your specific needs

- Various probes allowing the characterization of a wide range of sizes and materials

- Fast, non-destructive and easy to use due to user-friendly and customizable software

Equipments:

CSM-Win Systems Capabilities

Whether you require a simple C-V plotter to measure mobile ion contamination or an advanced system to measure multi-frequency C-V, I-V, TVS, or gate oxide integrity, Materials Development Corporation… More Info

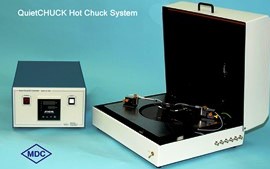

QuietChuck Hot Chuck Wafer Prober

This model provides unique capabilities for advanced MOS device measurements. Proportionally controlled direct current heating provides the most electrically quiet environment for high sensitivity capacitance and current measurements.

Mercury Probe

MDC MERCURY PROBES are precision instruments that enable rapid, convenient, and non-destructive measurements of semiconductor samples by probing wafers with mercury to form contacts of well-defined area.

441-150 Cryogenic

This model provides a shielded, electrically quiet, atmosphere controlled environment for high sensitivity capacitance and current measurements at near liquid nitrogen temperatures, 77°K.

Special Probes:

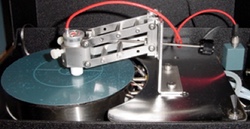

Special Arm with 4 Point Probe Head

Please contact us for more details.

Low Profile Probe Head for Hall Measurements

For use in making four point probe measurements associated with Hall measurements.

Calculator

Enter values for three of the four parameters and set the fourth value equal to 0.

The 0 value parameter will be computed when you click the Calculate button.

An approximate relationship between doping and breakdown voltage for a step junction.

Enter values for one parameter and set the other value equal to 0.

The 0 value parameter will be computed when you click the Calculate button.

Valid for silicon.

Uses ASTM formulae to convert between doping and resistivity for silicon.

First select type (n/p).

Then enter a value for one parameter and set the other value equal to 0.

The 0 value parameter will be computed when you click the Convert button.

Valid for silicon.