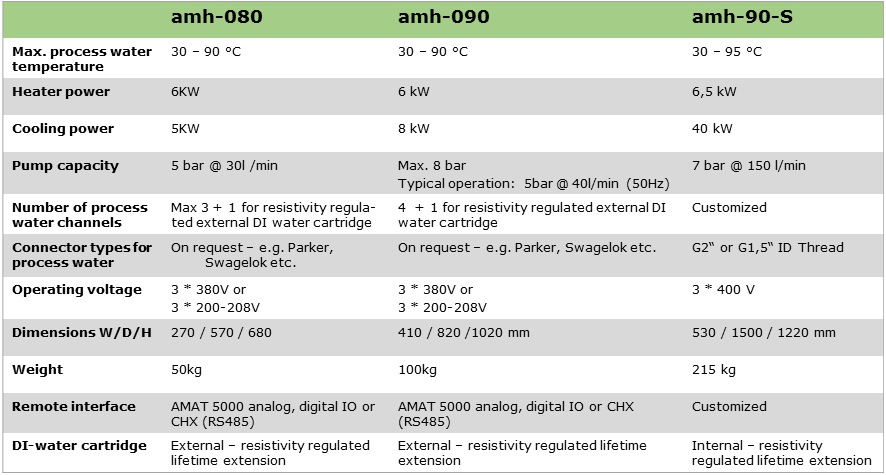

Heat exchangers for temperature range 30°C – 95°C

|

amh-080 Equipped with proprietary interface boxes for replacement of

|

|

|

amh-090 Equipped with proprietary interface boxes for replacement of

|

|

|

amh-090-S Compatible with Mattson Helios III & TEL MB Square -High-performance Grundfos pump with minimal maintenance (7 bar, 150 l/min) |

amh Heat Exchangers – Robust

For a long lifetime and low maintenance cost due to

- resistivity sensor & control resistivity-based regulation (on/off) of deionization

- balanced size of heating rod surface resulting in lower stress for heater and fluid as well as increased heating capacity

- pumps & pipes in stainless steel

- very robust hiqh quality pump

- robust construction – German quality product

|

|

|

|

|

amh Heat Exchangers – Flexible

Replacement for OEM Heat Exchangers

- Multiple control modes local, semi-remote, full-remote

- Supporting different remote interfaces AMAT 5000 Analog, Digital IO, CHX, RS-485,…

- Supporting different connector types for liquid media Parker, Swagelok,…

- Customer determines number of connectors for media in- and outlet

- Plug & Play no adaptations necessary, can be connected and operated immediately

- Operating voltage 208V/50Hz, 400V/50Hz

|

|

|

|

amh Heat Exchangers – Cost efficient

Sophisticated product features reduce costs noticeably

- Low initial costs outstanding price-performance ratio

- Low operating costs

– Minimized heat loss owing to heat insulated tanks and piping system

– Up to 10 times longer lifetime of DI-water cartridge due to resistivity-based regulation - Low maintenance costs

– Top quality components

– 2 years warranty

– Clear layout of components & easy to access

-> service by own maintenance personnel possible

|

|

Technical Data amh Heat Exchangers

A more detailed presentation of our heat exchangers

amcoss heating control units are a great solution to replace conventional, expensive, and even no longer available Heat Exchangers as e.g. AMAT 0 & 1, Neslab Steelhead and Endura and others.

amcoss heat exchangers configures and fits them according to clients’ demands. Due to adaptable and personalized interfaces, which amcoss prepares and builds in (substituting standard interfaces) the appliances are immediately available for „Plug-and-Play” operation at client’s equipment. That’s why the client will access custom devices configured for their own operation requirements and will not have to look for and implement solutions on his own. This also facilitates his sourcing activities and enhances cost-effectiveness.

Powerful design, long lifetime

amcoss amh heat control units are solid, stable and efficient – aspects that are quite necessary nowadays for sustainable activities. The usage of quality elements and pieces, a simple, solid construction and helpful functionalities as, e.g. the resistivity sensor, do expand the lifetime of amcoss appliances, minimize maintenance requirements and guarantee stable operations.

Because the heat exchanger devices are configured to replace heat control units specially conceived for certain processing machinery which, nowadays is no longer offered or assisted by the OEM, the amh appliances can actually increase the timing of using these machinery (AMAT, Neslab Steelhead, Endura, Hellios, MB Square, etc.).

Reduced energy consumption and „Plug-and-Play“ advantages guarantee a great efficiency of processes and costs.

Benefits of amh heat exchangers explained

Plug and Play option

amcoss Heat Exchangers represent for the clients ready-to-use devices. There is no need for adjustments and customizations to operate the existing equipment. The amh appliance can be inserted into the equipment string and operated promptly, reducing time and saving clients’ investments.

Solid and powerful

The long lifetime of amh heat exchangers is a consequence of its robust design. The whole piping structure is made from stainless steel, as well as the powerful high-quality pump. This also allows minimum service requirements. The size of the heat exchangers is configured to fit the dimensions of the heating rod surface. That’s why there is less strain on the heater and the fluid, which increases the heating capacity of the component as well as its endurance.

Various operational modes and displays

- Allowed operation modes: local, CHX, interface, DIO

- Multiple displays: system pressure, t° (0,1°C accuracy), resistivity of process water, and so on

- 3-step microprocessor controller with t° management and automatic enhancement

Resistivity sensor and control

amcoss heat exchangers are fitted with a resistivity sensor. This sensor manages the resistivity of the cooling medium and controls its deionization. Once resistivity falls below a threshold value fixed by the customer, the medium is being run over a deionization cartridge. As soon as the threshold value has been reached once again, deionization automatically ends.

- Benefits: resistivity of the cooling medium remains invariable and so does the entire process. The deionization cartridge has a longer endurance as it is not being permanently used. That’s why it reduces maintenance costs.

Multiple interfaces and connectors

- amcoss heat exchangers are compatible with several remote interfaces such as Digital IO, CHX (RS-485), and so on, and may be equipped with many connector types. Also the client may individually select among various couplings (Parker, Swagelok, etc.) for liquid media. The number of connectors for in- and outlets is confirmed by the customer. In consequence the appliance is built to be very customer – specific, providing more flexibility and compatibility with various applications.

Cost-cutting functionalities

- Reduced operational costs

amh´s solid pump is very efficient and energy-saving. All tanks and pipings are heat coated, which reduces heat loss through radiation. Endurance of the deionization cartridge is enhanced, because it is only being launched by the resistivity sensor which manages the cooling medium, if needed. - Reduced maintenance costs

amcoss heat control units are built by using only high-quality parts. A two-year warranty is offered. Structured layout of the pieces within the unit and fast accessibility allow easy maintenance operations to be accomplished by the operation assisting personnel. - Reduced acquisition costs

The great price-performance ratio led amcoss heat exchangers to acquire an important competitive advantage over similar devices on the market of heat exchangers..

Fill in the contact form and our service team will take care of your request!