PRECISION 4-POINT RESISTIVITY PROBE HEADS

FEATURE

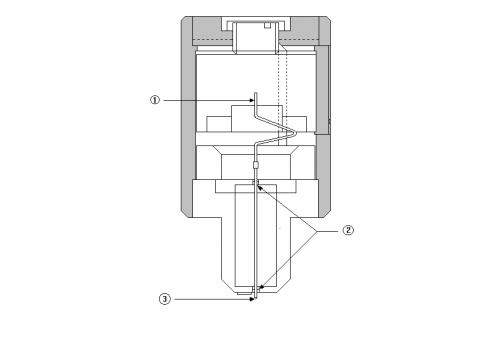

1. Anodized aluminum alloy upper and lower guides are jeweled.

2. Solid tungsten carbide needles for superior durability.

3. Teflon insulation gives minimum leakage

4. Loads checked by electronic force gauge

5. Spacing and tip radii optically checked for accuracy by

interferometer.

STRUCTURE

STANDARD SPECIFICATION

|

Probe spacing |

20,25,40,62.6 mils (0.5, 0.635, 1.0, 1.59 mm) |

|

Tolerance |

± 0.01 mm |

|

Arrangement |

Linear array. |

|

Needles |

Solid tungsten carbide ø0.40 mm 45°included angle, |

|

Other Material |

50% osmium alloy tips available. |

|

Radii |

0.5 mil to 20 Mils (12.5~500µ)polished. |

|

Planarity |

0.5 mm |

|

Planarity |

Better than 1 mil (0.025). |

|

Loads |

10g min. to 250g max. per needle (not user adjustable). |

|

Leads |

4-way cable Teflon insulated |

|

Leakage |

1013ohms resistance between needles at 100volts |

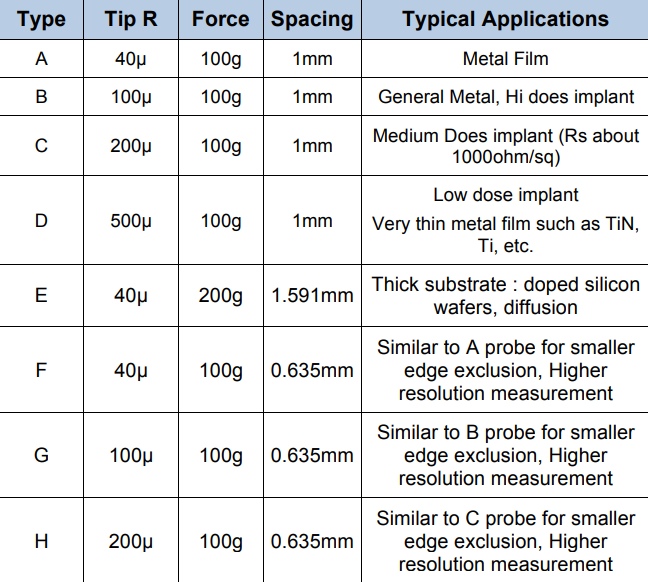

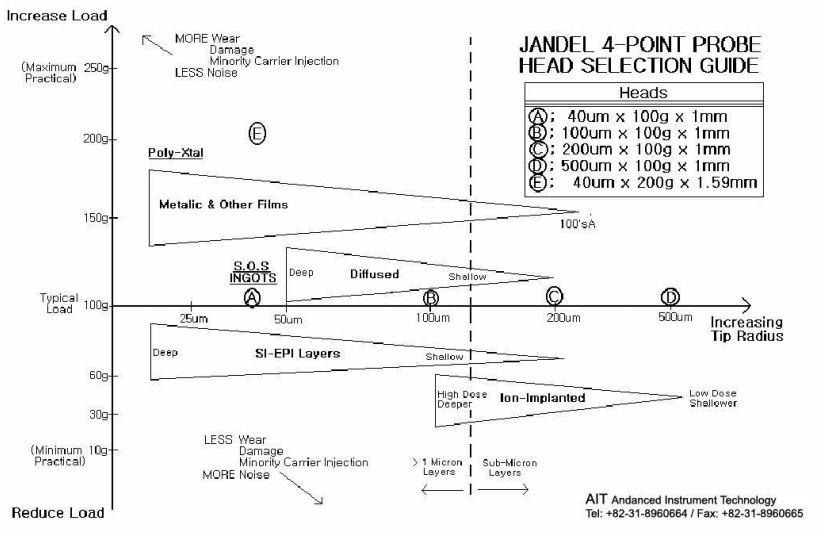

PROPER CHOICE

For most of the probes used, the only really important distinction is the tip radius, which affects the penetration or contract pressure. The most commonly used probes are given names as type A, B, C, etc. The following is a summary of the most popular probe types: