Whether you require a simple C-V plotter to measure mobile ion contamination or an advanced system to measure multi-frequency C-V, I-V, TVS, or gate oxide integrity, Materials Development Corporation…

C-V AND I-V MEASUREMENT SYSTEMS WINDOWS SOFTWARE

…has a computerized system for you. And that system comes complete with all necessary hardware and the most versatile Windows software available.

With years of development and testing behind it, MDC software features the largest choice of proven measurement and analysis functions. MDC carefully integrates all instruments, probe stations, multiplexers, and a computer into fully operational systems that provide the utmost in accuracy and ease of use. For customers who have their own hardware, MDC offers complete software packages to unify the equipment into a semiconductor measurement powerhouse.

MDC manufactures the widest variety of C-V and I-V plotting systems available. The CSM/Win Semiconductor Measurement System family includes over one hundred different instrument configurations.

Behind all CSM/Win Systems stands MDC, the company that introduced the computerized C-V plotter over two decades ago. MDC has the technical support and applications experience to serve you better and a continuing commitment to pioneer semiconductor analysis technology.

CSM/Win CONFIGURATION GUIDE

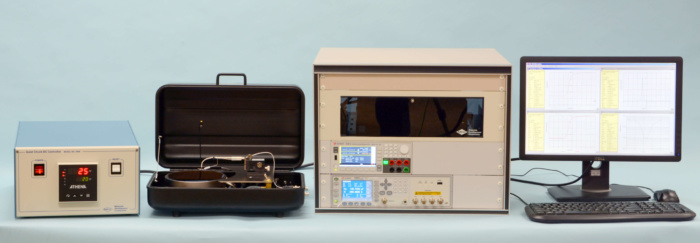

MDC will tailor your CSM/Win Semiconductor Measurement System for your exact requirements. Choose from the best capacitance meters and probe stations to suit your specific need. All CSM/Win Systems are rackmounted in a tabletop enclosure or stainless steel workstation.

CAPACITANCE METERS

MDC offers the latest instruments from Keithley, Keysight, and Hewlett-Packard to match every measurement need from routine production to advanced research. MDC experts will offer you a personalized and customizable system set-up tailored to your requirements.

PROBE STATIONS

MDC can integrate different probe stations suitable for production, engineering, or research applications. All systems can be customized and combined using multiplexers to improve efficiency. See individual data sheets for more details.

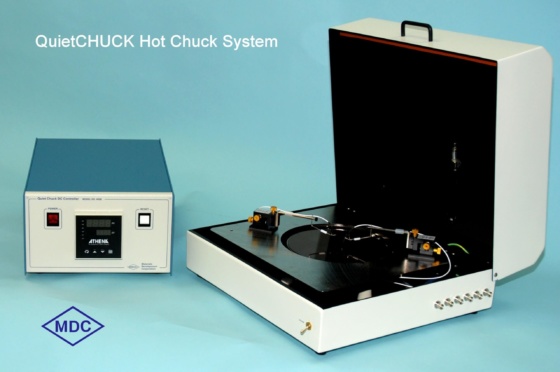

The QuietCHUCK Hot Chuck System is a complete hot chuck wafer prober package capable of measuring a wide range of parameters using CV and IV data. It also allows efficient mobile ion measurements to monitor for example furnace contamination by conventional bias temperature stress technique (CVBT) or triangular voltage sweep method (TVS). The MDC QuietCHUCK System uses a DC powered hot chuck controller for minimum induced noise. The CSM/Win System can control and monitor all stress parameters and includes expanded multiple test menus, data storage, and statistical analyses. Multiplexing of up to 10 probes is possible.

More info

Mercury Probes are used for efficient, non-destructive measurements at room temperature on a wide range of substrates (MOS device, bare semiconductor, oxide layer). Their high repeatability and ability to measure non-metallized samples, make them the perfect solution for research applications. Mercury Probes are excellent for monitoring a wide range of parameters such as wafer doping and resistivity. Mercury probes work well with various materials including SiC, GaAs, GaN and GaP. The probes work in both front- front and front-back contact configurations.

More info

441-150 Cryogenic Probe Station providing a shielded, electrically quiet, atmosphere controlled environment for high sensitivity capacitance and current measurements at near liquid nitrogen temperatures, 77°K.

More info

ION IMPLANT ANALYSIS OPTION

Ion Implant Analysis software allows the user to model implants with various doses, energies and cap materials. Compute active dose, range, and straggle. The user can overlay theoretical and actual plots for comparison.

THIN FILM TRANSISTOR MEASUREMENTS

The Thin Film Transistor measurement option provides a menu of three-terminal tests to evaluate device performance. Plots showing transfer, output and saturation characteristics are measured. Special analyses include ION, IOFF, mobility, and threshold voltage.

MULTIPLE PLOT OVERLAY

The CSM/Win software makes it easy to overlay plots from different measurements for comparison. Simply click and drag one plot onto another to combine them.

HELP FILES

The CSM/Win Help file is available at a mouse click. It provides practical measurement information, details of each measurement mode, specifications, and maintenance information. The Help file also contains a collection of ideal and anomalous plots, a reference list, and even a spare parts list. At over 500 pages, the CSM/Win Help file is an invaluable resource.

CUSTOMIZED SOFTWARE

CSM/Win System software already provides a spectrum of tests that span both production and engineering evaluations of many types of semiconductor devices. MDC software engineers can use their experience to develop custom applications for special measurement needs. Modifications can range from a small variation on an existing measurement to an entirely new test.

CSM/Win SOFTWARE FEATURES AND CAPABILITIES

Materials Development Corporation offers the most advanced C-V plotting systems incorporating the latest instrumentation and Windows software. The accuracy of MDC CSM/Win Systems is unsurpassed and the variety of measurements and analyses available is unmatched. Select from these menu options:

PRODUCTION C-V MEASUREMENT

Accuracy and control are the key words for MDC production C-V measurements. CSM/Win production software offers a streamlined C-V plotting and bias -temperature stress program with minimum operator input. A click of the mouse begins the measurement. A single display shows all plots and test results. Password protection allows a supervisor to preset all C-V measurement and stress cycle parameters. Production test results may be saved for later retrieval and analysis. Complete plots or just summaries may be stored. Data can also be entered in the CSM/Win database for trend analysis using various control charts.

MOS C-V MEASUREMENT AND ANALYSIS

The user can select from three different data gathering modes: Swept, Retrace or Pulsed. Each mode examines the MOS device under different conditions. The Swept Mode finds the substrate doping, flatband voltage, threshold voltage, and mobile ion concentration. An important feature of the Swept Mode is the Light Flash and Stabilization. This assures that the MOS device has reached equilibrium inversion capacitance before the sweep begins. Since the C-V sweep begins with the MOS device in inversion, errors due to sweeping rate and inversion capacitance determination while sweeping are eliminated. The result is a “textbook” C-V plot with no anomalous glitches. The Retrace mode shows hysteresis due to slow trapping or charge storage effects. The Pulsed mode prevents inversion and measures the deep depletion MOS C-V data needed for doping profile determination.

MOS CONDUCTANCE MEASUREMENT AND ANALYSIS

CSM/Win software uses conductance to give a complete picture of MOS devices and to correct for series resistance effects. MDC C-V plotters use both conductance and capacitance measurements to plot true device capacitance and depletion region conductance. Others just plot equivalent parallel capacitance or equivalent series capacitance while neglecting the depletion region conductance.

The conductance of the MOS capacitor is more strongly affected by interface charges than is the capacitance. Conductance is directly proportional to loss in the MOS structure due to charging and discharging of interface traps. Therefore CSM/Win Conductance-Voltage plots give valuable information about interface traps. The unique CSM/Win analysis of the conductance versus frequency characteristics of an MOS sample is the most sensitive C-V interface trap detection method and is capable of resolving charge densities in the low 109 cm-2 eV-1 range.

MOS DOPING PROFILE ANALYSIS

CSM/Win software uses the comprehensive Ziegler algorithm to convert pulsed MOS C-V data to a doping profile. The doping profile is accurate from the oxide-semiconductor interface to the maximum depletion depth and is therefore useful for low dose ion implant monitoring. Peak doping, range, and total active dose are computed. The technique is sensitive enough to resolve changes in the substrate doping profile due to redistribution during oxidation.

MOS CAPACITANCE-TIME MEASUREMENT AND ANALYSIS

The Capacitance-Time transient resulting from an MOS device pulsed into deep depletion reveals important information about bulk properties of the semiconductor and about damage or contaminants introduced during processing. The Zerbst analysis gives carrier generation lifetime and surface recombination velocity. An additional analysis of lifetime versus depth can measure lifetime uniformity in epitaxial layers and can detect differences due to denuded zones or implant damage. Measurements can be made at elevated temperatures to accelerate recovery time.

DIODE MEASUREMENT AND ANALYSIS

A comprehensive set of analyses for junction diode or Schottky barriers begins with C-V data gathering. The voltage step automatically adjusts to the slope of the C-V characteristics. This assures an optimum set of C-V data whether the voltage range is small or large. Doping and resistivity profiles are both available at the click of a mouse. Plots of 1/C 2 -V or Log(C)-Log(V+ ) show doping uniformity and doping slope factor. Exclusive recalculation options allow adjustment of stray capacitance and area to facilitate calibration using a standard reference wafer of known resistivity.

PRODUCTION RESISTIVITY PROFILING OPTION

Using a Mercury Probe, the user can quickly measure the resistivity or doping level of a bulk wafer or epitaxial sample. The program offers on-screen averaging of doping or resistivity and a single detailed display of test results. The optional Mercury Probe calibration software uses a reference standard to automatically measure probe contact area and stray capacitance.

INTERFACE TRAP DENSITY ANALYSIS OPTION

CSM/Win software offers interface trap density analysis using both the Conductance-Frequency and Quasi-static techniques. The Conductance-Frequency method is recommended for fine-tuning of processes where the highest resolution is needed. The Quasi-static technique is recommended where moderate to high levels of interface traps are monitored, such as in radiation damage studies.

TRIANGULAR VOLTAGE SWEEP (TVS) OPTION

The TVS method measures the current-voltage characteristics of an MOS device at high temperature. This technique, which allows direct measurement of mobile ion movement, has higher sensitivity and is much faster than the conventional CVBT measurement. CSM/Win software uses a unique on-screen technique to accurately analyze TVS data. The MDC QuietCHUCK DC Hot Chuck System contributes to superior TVS data from the CSM/Win Systems.

CURRENT-VOLTAGE/OXIDE INTEGRITY OPTION

CSM/Win Systems with an I-V option can measure both MOS and diode structures. For junctions, both forward and reverse bias curves can be analyzed. Junction ideality factor, series resistance, and reverse saturation current are found. Solar cells can be checked for efficiency. Oxide integrity of MOS devices can be evaluated by various techniques such as Time Dependent Dielectric Breakdown, Charge to Breakdown, and pulsed or ramped voltage. Present data using histograms, cumulative failure plots, or Weibull plots.

CSM/Win SEMICONDUCTOR MEASUREMENT SYSTEM

Calculated Parameter Specifications

The following is a list of calculated parameters generated by the CSM/Win series of SEMICONDUCTOR MEASUREMENT SYSTEMS. Typical parameter ranges and accuracies are given. Note that the accuracies given can be significantly affected by user supplied values such as device areas and oxide thicknesses.

JUNCTION DOPING PROFILES:

Range: 1×1013 ions/cm3to 1×1018 ions/cm3, 0.01 microns to 100 microns. Depth and doping ranges limited by zero-bias depletion width, breakdown voltage, and instrument voltage range.

Typical Values: Doping: 1×1015 ions/cm3, Depth: 1 micronto 17 microns. Doping: 1×1016 ions/cm3, Depth: 0.33 microns to 2.5 microns.

Accuracy: Typically ±2%, dependent on supplied device area.

MOS DOPING PROFILES:

Range: 2×1014 ions/cm3 to 5×1017 ions/cm3, 0.01 microns to 10 microns. Depth and doping ranges limited by bulk breakdown voltage of semiconductor, oxide breakdown, and instrument voltage range.

Typical Values: Doping: 1×1015 ions/cm3, Depth: 0.01 microns to 5 microns. Doping: 1×1016 ions/cm3, Depth: 0.01 microns to 2 microns.

Accuracy: Typically ±5%, dependent on supplied device area.

IMPLANT DOSE CALCULATIONS:

Range: 5×1010 ions/cm2 to 5×1012 ions/cm2.

Accuracy: Typically ±8%, dependent on supplied oxide thickness.

LIFETIME:

Range: 0.1 microsecond to 0.1 second.

Typical Values: 100 microseconds to 1000 microseconds.

Accuracy: Typically ±8%, dependent on user supplied parameters.

FLATBAND VOLTAGE SHIFT:

Range: 0.005 Volts to 50 Volts.

Typical Values: 0.05 Volts to 0.2 Volts.

Accuracy: Typically ±2%, or ±0.005 Volts, dependent on supplied oxide thickness.

MOBILE IONIC CHARGE CONCENTRATION:

(Bias -Temperature Vfb Shift Method)

Range: 1×1010 ions/cm2 to 1×1013 ions/cm2.

Typical Values: 3×1010 ions/cm 2.

Accuracy: Typically ±2%, ±1×1010 ions/cm2, dependent on user supplied oxide thickness.

MOBILE IONIC CHARGE CONCENTRATION:

(Quasi-static/TVS Method)

Range: 1×109 ions/cm2 to 1×1012 ions/cm2.

Typical Values: 3×1010 ions/cm2.

Accuracy: Typically ±5%, ±1×109 ions/cm2, dependent on user supplied oxide thickness.

INTERFACE TRAP DENSITY:

(Quasi-static/High Frequency Method)

Range: 2×109 ions/cm2 /eV to 1×1012 ions/cm2/eV

Typical Values: 3×1010 ions/cm2/eV, midgap.

Accuracy: Typically ±10%, ±1×1010 ions/cm2/eV, dependent on user supplied parameters.

INTERFACE TRAP DENSITY:

(variable Frequency Method)

Range: 2×109 ions/cm2/eV to 1×1012 ions/cm2/eV

Typical Values: 2×1010 ions/cm2/eV, midgap.

Accuracy: Typically ±7%, ±3×109 ions/cm2/eV, dependent on user supplied parameters.

CURRENT VOLTAGE PLOTS:

Range: ± 100 Volts, ± 10 fA to ± 1 mA.

Accuracy: Typically ±1%.

JUNCTION DIODE PARAMETERS:

Range: Rs: 0.1 to 1000 Ohms, Is: 1×10-13 to 1×10-8 Amps, n: 1.0 to 2.0.

Typical Values: Rs: 2 Ohms, Is: 1×10-11 Amps, n: 1.2.

Accuracy: Typically ±5%.

OXIDE BREAKDOWN FIELD:

(Ramped Voltage or Forced Current Method)

Range: 0 to 20 MV/cm.

Typical Values: 8 MV/cm.

Accuracy: Typically ±5%, dependent on user supplied oxide thickness.

NOTES:

1. Calculated parameter accuracies are given for

measurements where appropriate corrections, such as those

for series resistance effects, have been used. Large errors

may result where needed corrections are not performed.

2. Some of the parameters listed are obtained only by using

special options such as a quasi-static option, a

current-voltage option, or a variable frequency option.

3. Some of the parameter accuracies shown may be affected by

the type of capacitance/conductance meter used.

4. Doping and depth ranges assume a CSM/Win with ± 100 Volt

bias range.