Proven tool for FEOL and BEOL processes.

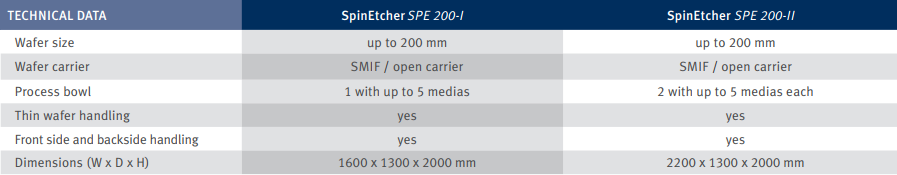

SpinEtcher SPE 200

BENEFITS

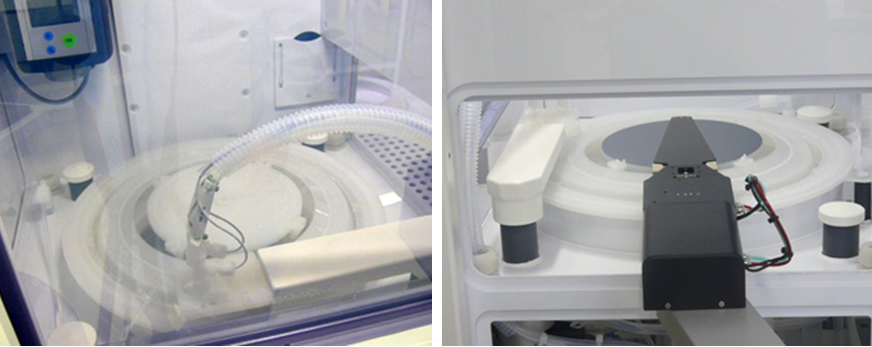

> Up to 5 media in one process bowl

> Backside protection chuck

> Low chemical and water consumption

> Chemical recirculation and recycling

> Front- and backside handling selectable in the recipe

> High safety levels for chemicals

> Easy upgrade to second process bowl

> Easy to change wafer size

> Optimized footprint

APPLICATIONS

The SpinEtcher SPE 200 is designed for processes like:

> Roughness etching

> Stress relief

> Polishing

> Film removal

OPTIONS

> Thin wafer handling

> Mini chemical dispense and mixture systems

> Endpoint detection

> Concentration monitoring

> Spiking unit

> SECS GEM interface

> SMIF or open carrier handling

> Wafer ID/Barcode reader

> Efficient chuck and bowl cleaning system

> Ionization unit