The modular, versatile single wafer system for etching, cleaning, lift-off, coating and developing.

SpinStep Flex line – The modular, versatile single wafer system SpinStep Flex line is designed for etching, cleaning, lift-off, coating and developing

BENEFITS

> Modular design

> Customizable and extensible (i.e. semi- to fully automation,

adaption of second process bowl)

> Different chemical supply systems are available

> Different processes in one bowl possible

> Easy to change the wafersize

> Optimized footprint

> Two tool sizes are available (Tool size 1: up to 200mm wafer,

tool size 2: from 200 to 300mm wafers and substrates)

> User friendly and easy to use; operation and tool control via

15’’ touchpanel

APPLICATIONS

The SpinStep Flex line is designed for the following processes:

Semiconductor – Clean:

SC1, SC2, Piranha, DIW, Post CMP clean, DO-O3

Semiconductor – Etch:

Etch/ Siliziumoxid (Clean), Etch/ Siliziumoxid, Etch Silizium

Semiconductor – Lift-off:

Our new patent pending lift-off process

Semiconductor – Coating and developing:

Positiv – negativ spray / puddle coating and developing

Semiconductor – Mask processor:

Cleaning, coating and developing

Mini Chemical Management System

Mini Chemical Delivery System (MCDS)

Mini Chemical Waste System (MCWS)

Mini Chemical Mixing System (MCMS)

Mini Chemical Recirculation System (MCRS)

Mini Chemical Spiking System (MCSS)

Options

> Megasonic system (MEGPie, Nozzle)

> Highpressure system

> Single side brush

> Mixing nozzles

> Puddle nozzles

> Pre-Soak

> Chamber rinse

> Media heating system

> Programmable dispense arms

> Drain separation system

> Fire suppression system

> SECS II GEM Interface

> FM 4910 compliant

> Vacuum, low contact chuck

> Backside protection chuck

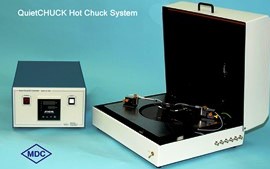

> Cool- Hot-plate stacks

> HMDS primer module