Jandel Engineering Limited manufactures the cylindrical four point probe head to be compatible with the Jandel Multiposition Wafer Probe, the Microposition Probe, the Multiheight Probe,…

…The Multiheight/Microposition Probe, as well as some OEM mapping systems. It can be built into customer engineered four point probe systems using an optional mounting adapter which Jandel offers. All Jandel probes are built to a high level of mechanical accuracy. Specifications for radii, spacing and planarity are verified by video inspection system and optical interferometer. Loads are verified by electronic force gauge. Each probe has upper and lower jeweled needle guides.

|

Probe spacing |

0.500mm, 0.635mm, 1.00mm, 1.27mm, 1.591mm (needle to needle) |

|

Tolerance |

+/- 10 microns |

|

Arrangement |

Linear or square array |

|

Needles |

Tungsten carbide 0.4mm diameter (0.3mm diameter for close spacing) |

|

Needle option |

50% Osmium alloy tips are available |

|

Radii |

12.5, 25, 40, 100, 150, 200, 300, 500 microns |

|

Retraction to pad |

0.5 mm |

|

Planarity |

+/- 0.025mm or better |

|

Loads |

Low: 10-30g Medium: 30-60g High: 60-150g |

|

Leads |

4-way screened cable, teflon insulated |

|

Electrical leakage |

1013 ohms resistance between needles at 500 volts |

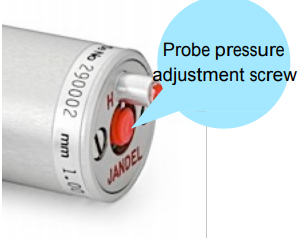

Probe pressure adjustment

The ranges are: 10-30g, 30-60g, and 60-150g. Within a range the load is adjusted by turning the pressure adjustment screw clockwise. The load indicator goes clockwise from ‘L’ (low load) round to ‘H’ (high load).

Optimum probe pressure

The probe has a plastic insulating pad on the nosepiece. It is intended that this pad is in contact with the measured sample when a measurement is being made. This ensures that the needles are retracted the correct distance and that the optimum indicated load is achieved.